Quantification of Environmental Effects from Fuel Production: An LCA Study to Help Enhance the Sale of Torrefied Wood Products to the European Union

Torrefied wood pellets are an energy source with potential to partially displace coal use in power plants, reducing global warming impact of electricity production. Torrefied wood is produced by heating wood at high temperatures without oxygen. The final product is resistant to moisture and biological degradation, has an energy density close to that of coal, and can be ground up easily. These properties allow for pellets to be easily stored, transported, and directly co-fired with coal without costly adjustments to existing plants.

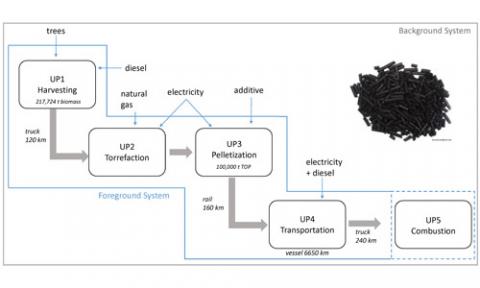

NSRC researchers conducted a hypothetical life cycle assessment of torrefied wood pellets produced by a facility announced for construction in Maine and shipped to the European Union (EU) for combustion. They assessed resources and associated emissions that pellets require and set free, from growing a tree to ash waste after combustion. Environmental impact factors, such as global warming potential (GWP) of carbon dioxide equivalents (CO2eq) over 100 years, are used to compare results from different products. Researchers found that the highest impact on GWP is created by transporting pellets from Maine to the EU. Truck, rail, and transatlantic shipping require significant amounts of fossil fuels and emit significant amounts of CO2.

On average, 90% net savings of CO2eq of pure torrefied wood pellets compared to pure coal can be realized. Using pellets to partially replace coal use in power plants has great potential to reduce associated GWP. Pellets represent a new, value-added forest product, and further research will investigate if this new demand on the Northern Forest can be met by current logging residue or if additional harvesting is required.